Commercial tires can range from major brands to China or China-affiliate off-brand options.

For commercial tire casings that have viable life remaining, the option of retreads for the casing can have value.

Which commercial tire option is right for you? That takes some planning and understanding of your business needs. We have outlined some typical scenarios to review and understand the value and performance for new commercial tires or retreads.

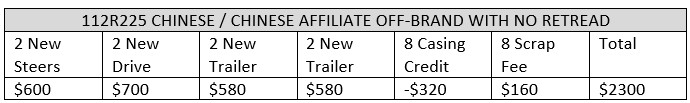

Fleet A is looking for the least expensive tire at time of purchase. He may not qualify for National Account pricing and selects a “less expensive” China or China-affiliate off-brand tire, not considering the up to 50% less useful tread life or the full lifecycle value of the casing once the tread is worn.

Outcome of this scenario is that the fleet had to buy a second set of tires to make up for shortened tread life. While this fleet may not qualify for bulk pricing, there could still be more value in a major brand tire that typically provide twice the mileage of China off-brand options, plus has the added value of an extended casing life which can benefit from retread.

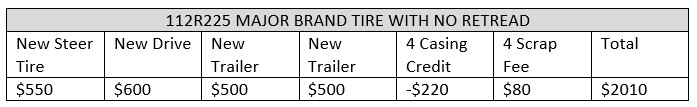

Fleet B purchases new major brand tires (ie: Continental). He qualifies for Continental National Account pricing. They see the value in the longer mileage that major brand tires offer. However, they never consider retreading as an option.

Outcome of this scenario is that depending on use, the fleet could be leaving valuable casing life behind.

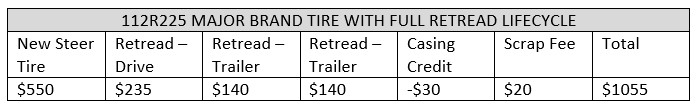

Fleet C purchases the same new major brand tires (ie: Continental) and qualifies for National Account pricing. They also opt to use retreads to extend the life of the valuable casing which still has life left when the tread wears.

The positive outcome here is shown in the total cost savings from utilizing the full lifecycle of the casing.

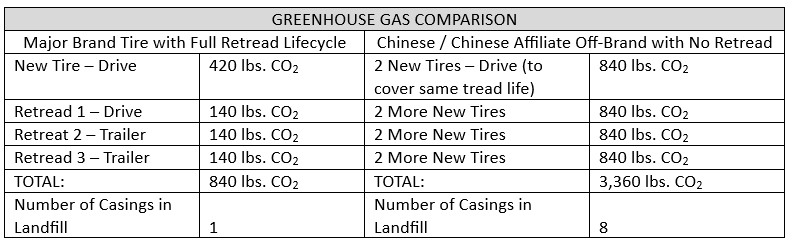

If reducing greenhouse gases and decreasing the number of tires in land fills is an important part of your company promise, retread tires can be instrumental to carrying through on reducing your carbon footprint. New tires require 3 times the amount of petroleum products in the manufacture process than that of a new tread compound adhered to the used casing. Based on our examples above, quality casings can be retread up to 3 times.

These select scenarios showcase where retread is a viable option, but overlooked. Today, most major tire brands are guaranteeing three retreads for their casing. Most China and China Affiliate off-brand tires don’t guarantee even a single retread because the casings are too narrow and lower quality to support the required casing width once worn tread is buffed off.

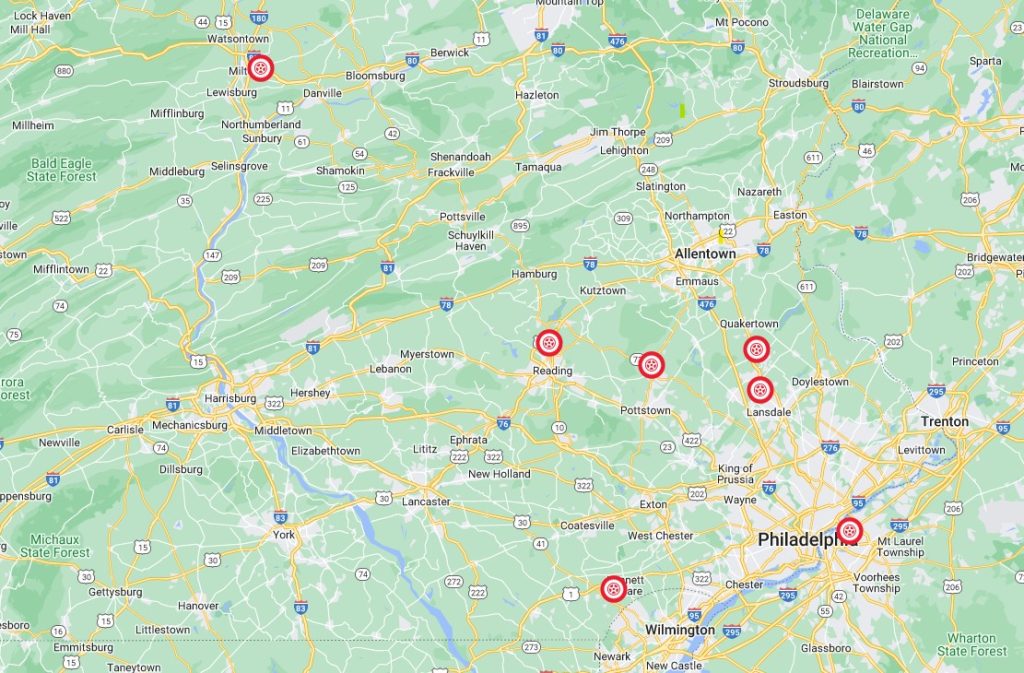

Retread may not always be the best solution for your fleet, or maybe you opt to only retread for trailers vs drive tires. Your best bet is to talk through your typical fleet usage and mileage with a commercial tire expert who can evaluate your needs and provide options that will give you the value, productivity and performance you need to keep your fleet moving. Bergey’s Commericial Truck Tire has 6 locations for sales, service and mounting, as well as a Retread production plant.

*All pricing and casing credits are estimated for example purposes only. We based pricing and casing credits at market value at the time of publication.