Bergey’s Truck Centers is proud to offer DPF cleaning using pneumatic air cleaning as well as thermal high-temperature oxidized cleaning using state-of-the-art FSX Equipment. And, with an average turnaround time of 24-48 hours, we can get you back on the road in no time! Let’s take a look at diesel particulate filters and how a proper DPF cleaning can help reduce unnecessary costs which would affect your bottom line.

In 2007, diesel particulate filters (DPFs) were introduced to on-road heavy-duty diesel engines as a way to trap diesel particulate matter to meet the EPA’s emission standards. The two compounds in diesel exhaust that have the most impact on the environment are NOx and particulate matter, commonly called “soot”. According to the EPA, particulate matter and NOx emissions found in diesel exhaust can cause serious health problems such as lung damage and aggravate existing respiratory illnesses such as asthma. The DPF is a ceramic filter with thousands of micropores that trap PM and ash and uses heat to oxidize it. What exits, is much cleaner air. To ensure that the DPF continues to function properly, fleets must implement a maintenance schedule for cleaning and maintaining the DPF. Failure to properly maintain the DPF can result in damage to the rest of the aftertreatment system.

DPF cleaning is not only critical for proper aftertreatment system maintenance, but it also helps improve diesel engine performance and fuel economy. Our DPF cleaning service allows us to help our Customers with a quality DPF clean and return with an average 24-48-hour turnaround. Our equipment is strategically located at three of our dealerships so that we can provide this service to our entire Truck Center footprint whether the truck is in our shop or a Customer brings it to any of our locations.

Steve Forde, Regional Service Manager

On average, a DPF filter needs to be cleaned every 250,000-350,000 miles. However, any specific filter may get clogged or blocked sooner than that, especially if the truck is on the highway less, and spends more time running at lower speeds such as refuse or construction vehicles. We utilize a 2-step method to ensure a thorough cleaning utilizing the FSX TrapBurner™ Thermal DPF Regenerator and FSX TrapBlaster™ Pneumatic DPF Cleaner. Here are some of the signs that your DPF filter is clogged:

Based on our findings, all DPFs which receive a stage 2 thermal cleaning show a better flow rate than those just cleaned with a pneumatic cleaner. The FSX TrapBurner™ thermal regenerator heats the DPF to oxidize soot and loosen hardened ash and is baked for 12 hours at one of our three DPF cleaning facilities. The thermal process uses ambient air while heating, reducing the risk of cracking the filter or causing any thermal stress.

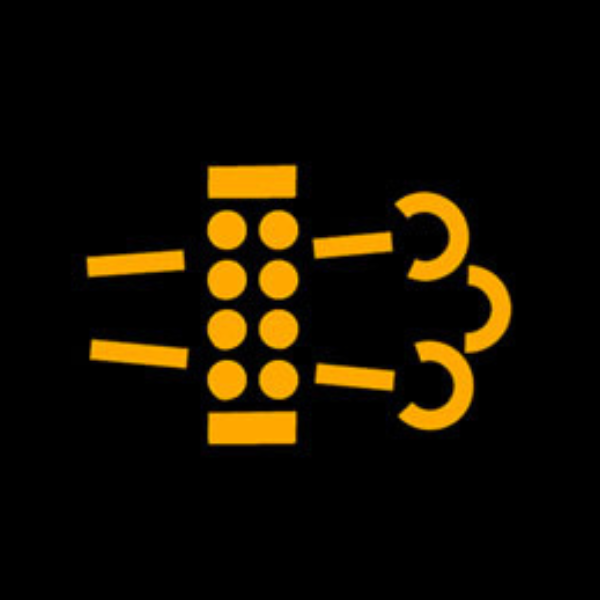

After the DPFs are baked we clean the filter with the FSX TrapBlaster™ which utilizes a bi-directional air knife scanning technology that prolongs the life of the DPF by cleaning each cell on both sides of the filter. After the pneumatic cleaning, we bench-test the DPF for proper flow.

Contact us today to learn more about DPF Cleaning or to schedule an appointment.