Bergey’s Acquires Susquehanna Motor Company

Bergey’s has acquired the assets of Susquehanna Motor Company in West Milton, PA The acquisition of Susquehanna Motor will allow Bergey’s to expand their brand

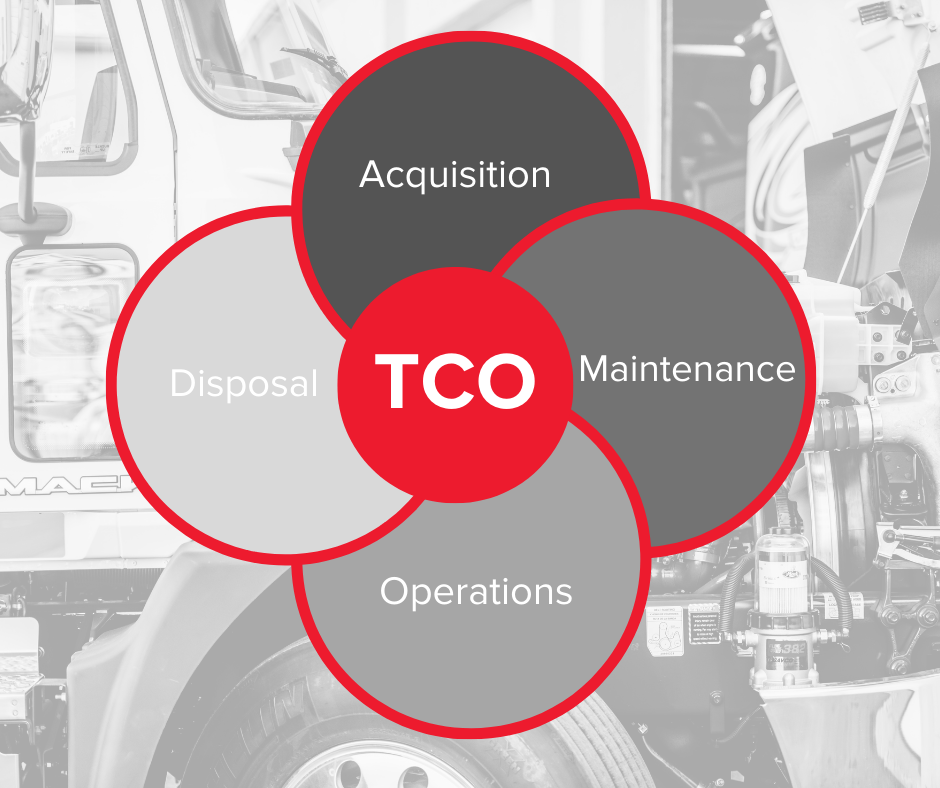

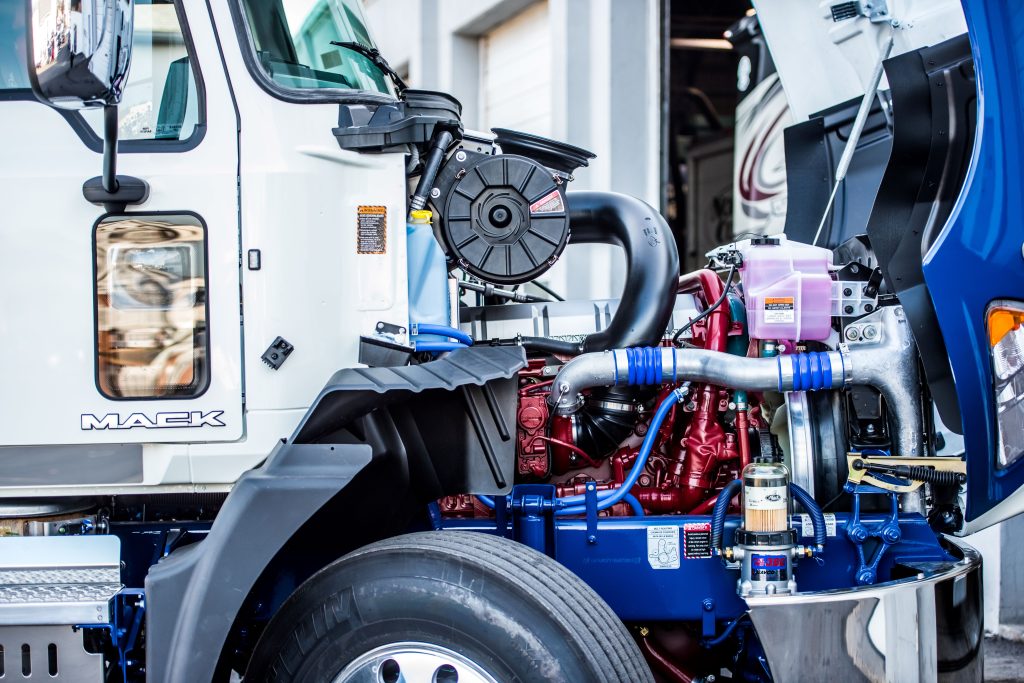

TCO is a critical data point for today’s fleets, but many fleet managers struggle to accurately calculate their TCO due to limited data and constantly changing variables. But, with a little planning and some guidance, you can leverage this powerful data point to determine fleet efficiency, analyze acquisition methods and identify opportunities for improvement.

To properly calculate your fleet’s total cost of ownership, you need to consider all aspects of ownership – Acquisition, Maintenance, Operations and Disposal. Each area has their own unique costs associated with them.

There is no one size fits all when it comes to fleet management, which is why additional knowledge is powerful to help your team make smart decisions.

Contact us if you would like assistance determining your Total Cost of Ownership (TCO) as a complimentary consultation service. As a commercial truck dealer, we sell commercial trucks, as well as lease (our commercial truck fleet has 800+ units), so we are well versed in TCO analysis and we work with our customers to help them determine the right option for their needs.

Want to learn more about leasing from Bergey’s Truck Centers? Check out our Full-Service Leasing page.

Bergey’s has acquired the assets of Susquehanna Motor Company in West Milton, PA The acquisition of Susquehanna Motor will allow Bergey’s to expand their brand

The Commercial Vehicle Safety Alliance (CVSA) has set the dates for its annual Operation Safe Driver Week. This safe-driving enforcement initiative will be held July

Managing the 2027 EPA Diesel Emissions Regulations and Expected Pre-buy Running diesel trucks in your fleet means you should be aware of the coming 2027

The annual Commercial Vehicle Safety Alliance is gearing up for the CVSA 2024 Roadcheck this May. Will your fleet be ready? Be prepared to have